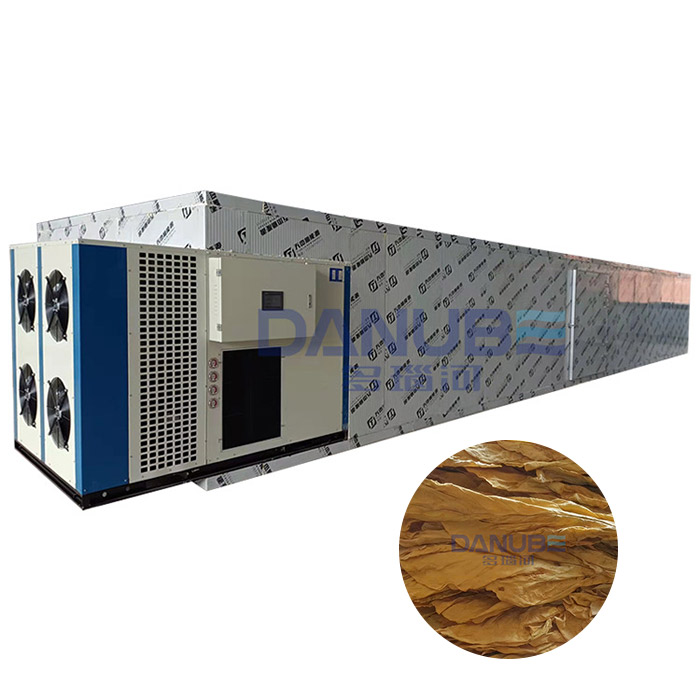

Tobacco drying machine introduction

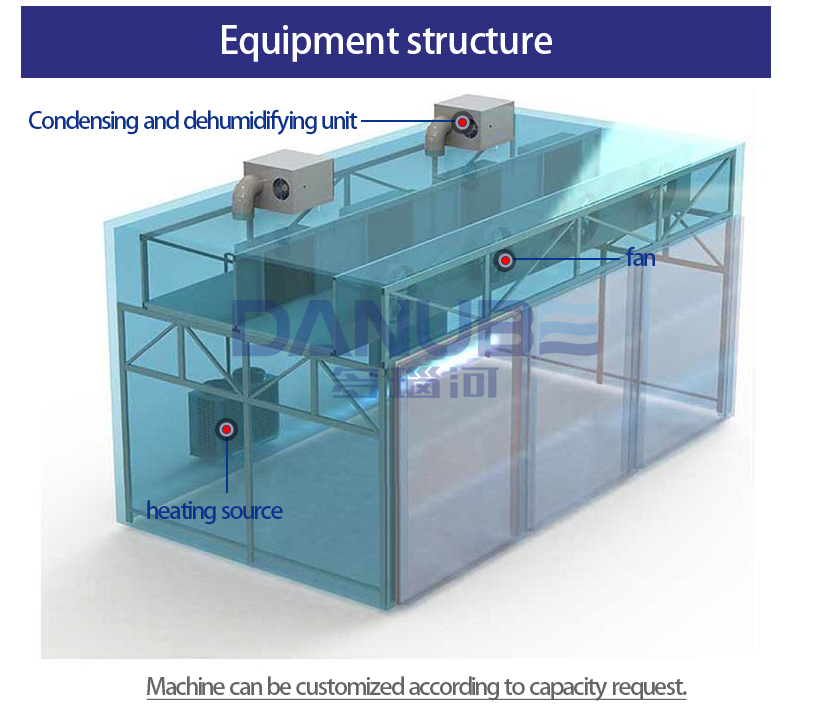

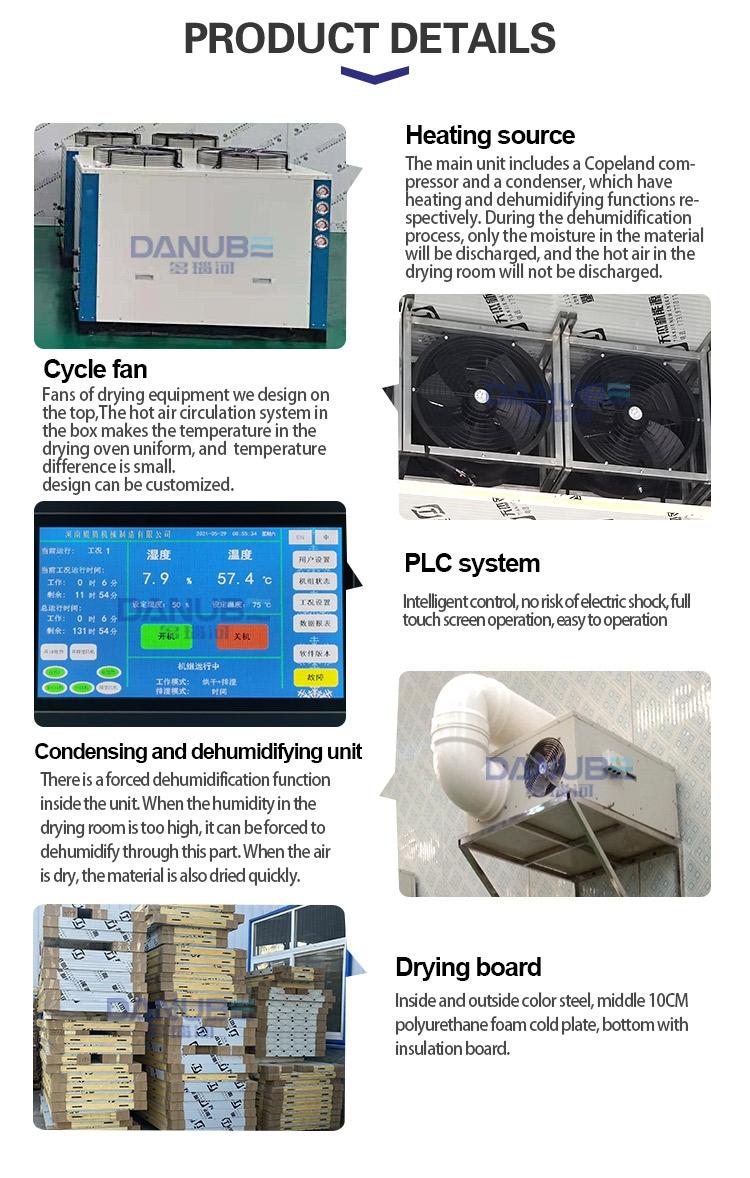

tobacco dryer uses reverse Carnot principle to allow hot air circulation blower to dry the material. Heat pump dryer Compressor – heat exchangers – Chokes – heat sink (outside the machine) – Compressor and other devices form a refrigerant cycle system. Fan wheel rotates, bringing outside air into the oven, hot air is formed, then enter the working chamber through the air distribution plate gap, bringing a lot of hot air inside the circulating flow, Continue to enter new air inlet supplement. After the recycled exhaust moisture from the exhaust port.The whole cycle, so that the material is heated uniformly, and the purpose of tobacco drying.

Tobacco drying is an important step in the tobacco production process, mainly using a dryer to stabilize and improve the quality of tobacco leaves by controlling temperature and humidity conditions.

Our tobacco leaf dryer can precisely control the drying temperature in sections, which will help the tobacco leaves to turn yellow more fully before moving to color fixation, thereby improving the quality of the dried tobacco leaves. Moreover, since the drying chamber is kept sealed, the CO2 released from the tobacco leaves increases the CO2 content in the drying chamber, which is conducive to the yellowing of the tobacco leaves and the formation of aroma-causing substances, thereby improving the intrinsic and appearance quality of the cured tobacco leaves and improving the aroma quality of the tobacco leaves. At the same time, automation, normalization and standardization are basically realized in the work process, so there is no need for dedicated labor input. One person can be on duty for multiple systems, will reduce a lot of labor cost.

Equipment on-site installation, simple operation, simple control, good temperature control, the company was founded more than 20 years, by professional technical research and development team, engaged in drying industry for more than 20 years, welcome to consult.