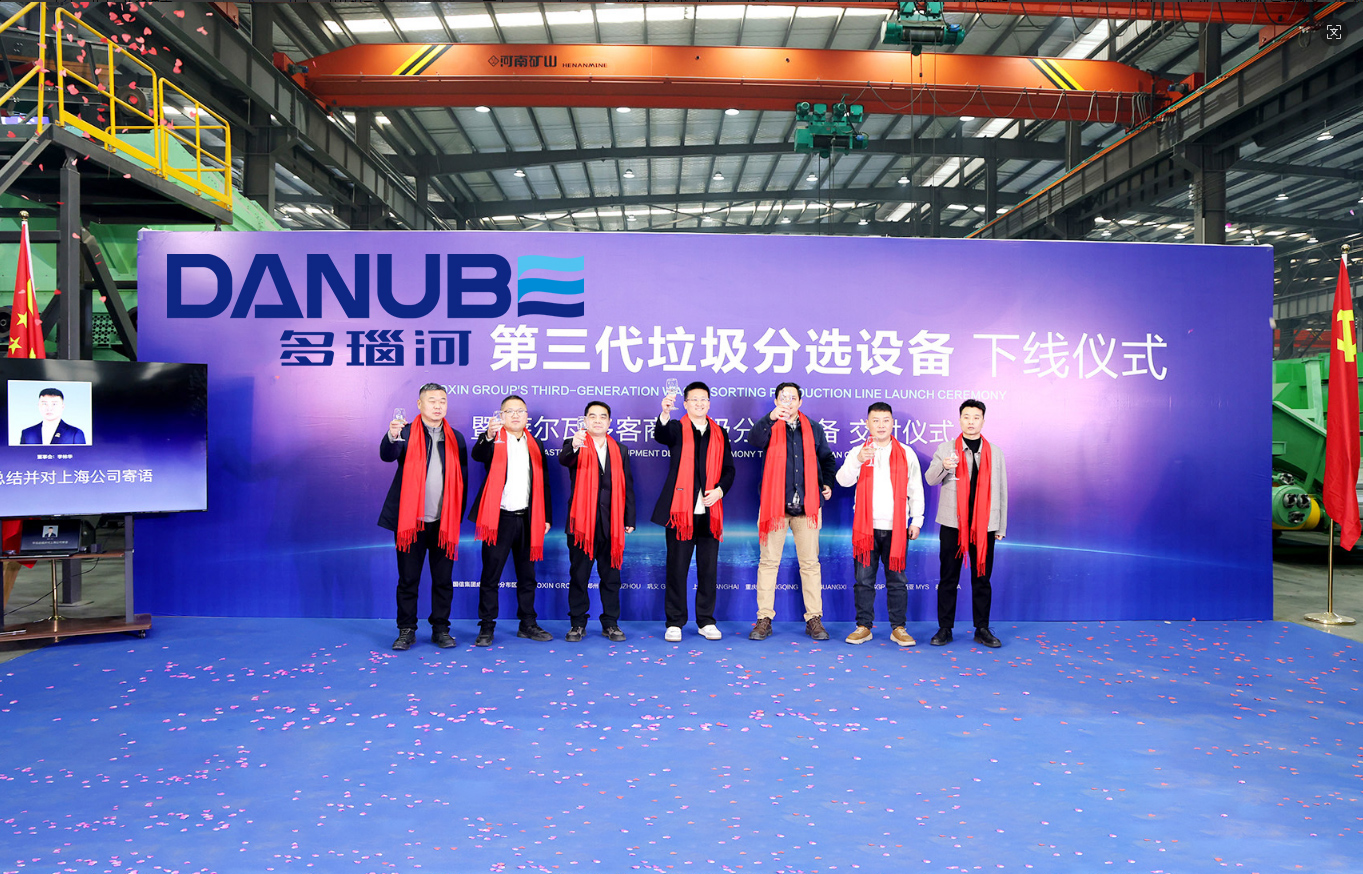

Recently, an inspection group from the Inner Mongolia Waste Sorting Project visited Danube to conduct a field investigation and in-depth exchange regarding solid waste treatment technology and automated sorting equipment. This visit aimed to introduce advanced technologies to enhance waste classification and resource utilization levels in the Inner Mongolia region.

The inspection group first attended a technical briefing at the group headquarters. Through a 3D simulation system displayed on a large screen, the group gained an intuitive understanding of the entire operational process of the waste sorting line, covering core processes from material input and physical screening to intelligent classification. Both parties engaged in rigorous discussions regarding key indicators, such as the equipment’s stability under extreme climates and sorting purity.

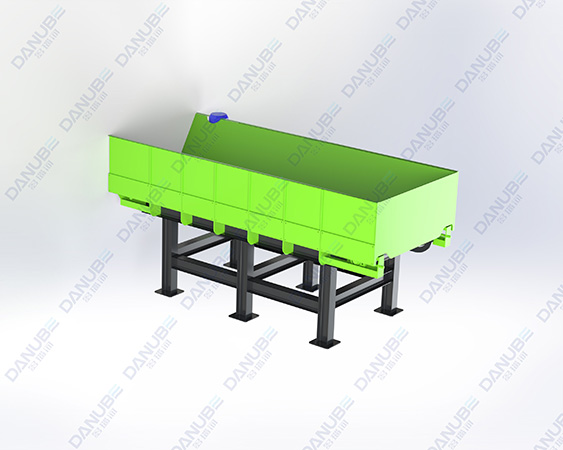

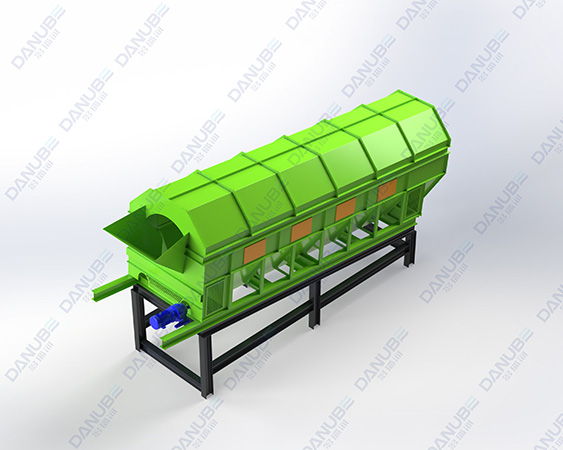

Subsequently, the group conducted a field study deep within the production workshop. At the busy and orderly assembly site, members closely inspected large-scale conveying equipment and automated sorting platforms currently under assembly, inquiring in detail about the durability of mechanical structures and post-maintenance costs. The large-scale manufacturing capabilities and exquisite industrial design demonstrated by Danube earned high recognition from the inspection group.

This visit not only strengthened mutual trust but also laid a solid foundation for the subsequent implementation of the project. Danube will continue to leverage its technical advantages to contribute to the development of a green circular economy in Inner Mongolia.

EN | CN

EN | CN