Recently, Danube Group’s production workshop buzzes with intense activity — multiple sets of waste sorting equipment, including core drum screens as key components, are being steadily and carefully hoisted onto large transport vehicles. These well-manufactured devices are set to depart for client project sites across different regions, undertaking important missions in waste resource utilization. Despite the approaching year-end, when many enterprises tend to slow down their work rhythm, the group’s shipment pace remains unslowed, fully demonstrating its commitment to fulfilling customer orders on time.

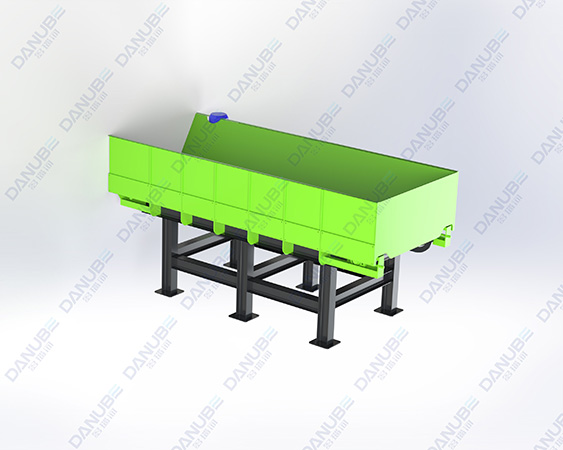

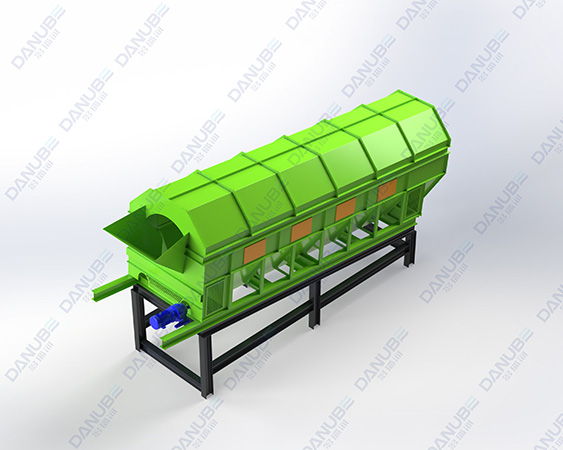

On-site, the large-scale drum screens with a distinctive green tone stand out prominently. A team of professional workers is meticulously inspecting every securing detail of the equipment on the transport vehicles, from the fixing bolts to the protective pads, to ensure absolute safety during long-distance transportation. As a core component of waste sorting systems, these drum screens feature advanced screening technology that can accurately classify mixed waste by particle size. This efficient pre-treatment process lays a solid foundation for the subsequent precise sorting and recycling of waste, making them widely applicable to domestic waste treatment plants, construction waste resource recovery projects, and other environmental protection scenarios.

“This batch of equipment is a custom model tailored for the client. We optimized the screen mesh apertures according to the specific characteristics of the mixed waste in their project, which can boost sorting efficiency by 30% compared with standard equipment,” noted a relevant representative of the group. Statistics show that Danube Group’s waste sorting equipment, which combines excellent durability and intelligent operation performance, has been exported to and served more than 130 countries and regions around the world, winning wide recognition from global customers.

From strict production inspection to careful loading and shipment, each piece of equipment undergoes multiple rounds of rigorous debugging to ensure its performance meets the highest standards. Moreover, Chairman Li Pengfei’s well-known philosophy — “Poor after-sales service is ungratefulness in business” — will also extend to every project site alongside the equipment. The group will dispatch professional technical teams to provide on-site installation guidance and follow-up maintenance services for customers.

The full-chain support from equipment production to delivery services is the solid cornerstone of Danube Group’s deep presence in the environmental protection equipment sector. It not only enhances the group’s core competitiveness but also injects more reliable momentum into the global waste resource recovery industry, contributing to the development of the green circular economy.

EN | CN

EN | CN