As the construction of “zero-waste cities” gains momentum, waste sorting equipment (a core component of solid waste recycling) is evolving toward higher efficiency and precision. At the front end of every sorting line, chain plate feeders and scale plate feeders serve as “frontline sentinels,” playing an important role in the uniform feeding of materials.

Waste sorting is challenged by highly complex material compositions, ranging from bricks and wood in construction waste to sludge and plastic in aged waste, which vary drastically in physical form, moisture content and corrosiveness. Thus, the selection of feeding equipment directly impacts sorting efficiency, equipment wear and recycling rates.

High-efficiency chain plate feeders are ideal for dry, bulk waste. Composed of chain plates, chains and sprockets, they have small gaps between plates— a design that rules out powder or wet-sticky materials but suits large-grain dry waste.

In contrast, scale plate feeders excel at handling complex materials, thanks to their seamless overlapping plates (resembling fish scales) that prevent powder leakage and wet material jamming. They are perfect for high-moisture aged waste containing sludge and humus.

Rather than competing, the two feeders work in flexible coordination based on material properties. As waste recycling technology advances, they are moving toward modularization and intelligence, playing an increasingly vital role in addressing the “garbage siege” and promoting the circular economy.

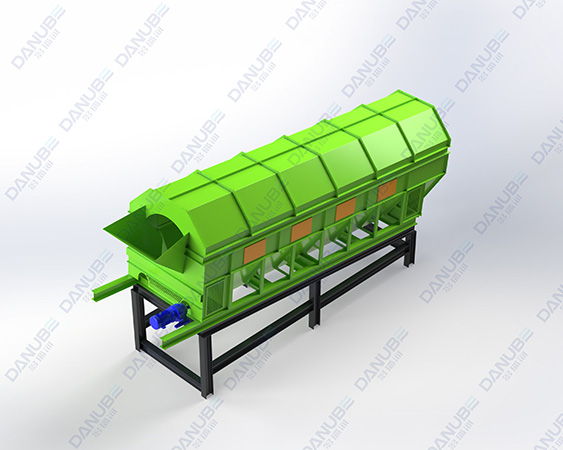

Scale Plate Feeders

Scale Plate Feeders

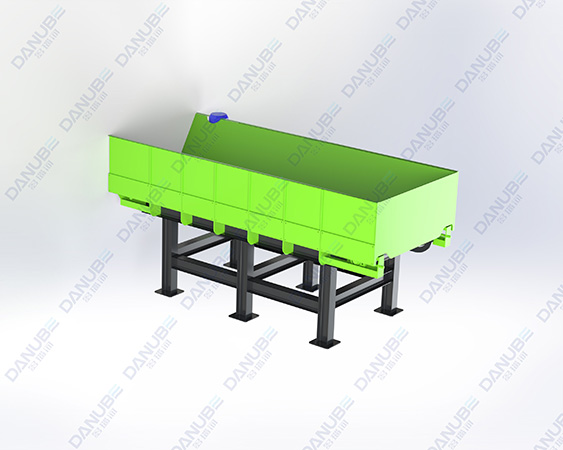

Chain Plate Feeders

EN | CN

EN | CN